Alumnus Michael Radigan Taking 3D Printing to New Heights

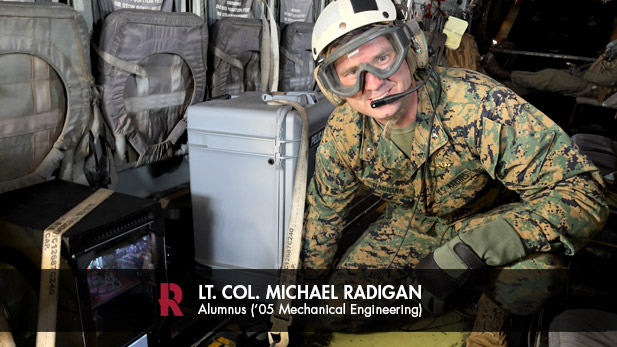

Lt. Col. Michael Radigan checks the progress of 3D printing a medical cast aboard an MV-22 Osprey during a June 2023 training flight. He is helping accelerate the adoption of advanced manufacturing capabilities for military uses.

Technology is soaring to new heights through innovative in-flight 3D printing techniques being pioneered for the U.S. military by a group that includes 2005 mechanical engineering alumnus Lt. Col. Michael Radigan.

As a Naval Postgraduate School liaison from the Marine Innovation Unit, Radigan is helping accelerate the adoption of advanced manufacturing capabilities like 3D printing to increase readiness in battlefield environments. These efforts spearheaded the first successful demonstration of in-flight 3D printing to simulate a rapid response for injured military personnel. The June 2023 demonstration created a medical wrist cast that was printed mid-flight aboard a Marine Corps MV-22 Osprey aircraft.

"Opening the door for mobile on-demand manufacturing from the air could be a game-changing capability for expeditionary operations," he said.

Radigan's involvement in inflight 3D printing builds on over two decades of military experience as an AH-1Z Cobra pilot, Weapons and Tactics Instructor, and additive manufacturing expert across defense agencies. "I love bringing together diverse, cross-functional teams and overcoming challenges to turn innovative ideas into operational realities that support our warfighters wherever and whenever necessary," he stated.

Beyond on-demand medical devices, 3D printers on aircraft, ships, and ground vehicles could produce spare parts, tools, shelters, and other critical equipment for troops in the field. "The ability to rapidly design and manufacture exactly what is needed, on location, could provide an enormous strategic advantage," he explained.

Radigan believes 3D printing can enable new logistical and operational concepts, like forward operating bases with land, air, and sea-based manufacturing facilities. "Logistics, maintenance, and medical support could all be radically transformed, right down to the tactical edge, by making additive manufacturing universally available,” he remarked. “Resupplying remote outposts using traditional methods can be challenging and costly. 3D printing will bolster the existing supply system for contested environment. A single aircraft carrying an array of printers can have the productivity of a small factory, delivered right to the point of need. The operational effects could be profound."

After being a reservist with the Marine Innovation Unit, Radigan returned to active military service earlier this year. He’s now pushing teams to think creatively about expeditionary applications because, as he said, “We're just scratching the surface on the capabilities that will come from mobile production at scale in a variety of platforms. I'm excited to see what's possible as we continue to optimize and expand this capability going forward."

As a Rose-Hulman alumnus, Radigan is proud to leverage his engineering education to champion new technologies for the Marine Corps. "Rose teaches you how to think about complex problems and deliver solutions that make a real difference," he noted. "That foundation has been invaluable throughout my career.”

Radigan exemplifies how Rose-Hulman graduates apply technical excellence and a can-do spirit to push boundaries and serve their country in groundbreaking ways.

“I enjoy using my interests in technology to discover new ways of looking at things, while helping others win by leveraging emerging technology,” he said.